Glass Floors and Fall Protection Glass

Safety is a major topic at isophon glas

Glass suitable for all requirements

While the task of most windows is to simply let light enter the building, glass from isophon can be used for floors, stairs and railings, as well as in order to withstand high weights.

isophon glas is a vendor for sophisticated overhead glazings and glass floors. Glass floor systems need to fulfill many more requirements and standards compared with vertically installed glass systems.

isophon glas will be happy to deliver glass floors suitable for people or even suitable for cars. If you want to cover an open space or widen a narrow crossover – glass floors can be the perfect solution for your application. The multiple layer structure results in a strong package of laminated glass which gives stairs, pedestals or floors the stability and weight resistance required for these projects.

LOAD CAPACITY AND POST-IMPACT LOAD CAPABILITY

There are two requirements glass floors must fulfill:

For one, the glass has to be able to carry its own weight as well as the additional weight. It furthermore has to be able to hold this load even when it breaks and this without any dangerous parts falling down.

Glass floors are set up with multiple layers of glass that all crack in different places. At least one layer of glass is a float glass or a semi-tempered glass while the other layers are tempered in order to increase the load capability. At least 3 glasses are combined to a package of laminated glass.

Glass floors need to comply with various standards. For example: DIN 18008 for building – construction and dimensioning. DIN 18008 chapter 5 specifies the requirements for glass that is safe to walk upon.

PENDULUM IMPACT TEST FOR SAFETY GLASS

Other standards such as EN 81 are used when you want to build fall resistant glass in elevators.

The standard DIN EN 12600 is based on DIN 52337 where the requirements are similar to the standards of the US standard ANSI 97.1-75..

To ensure the ability of the glass to prevent a collapse is determined with a so-called „pendulum impact test“ according to DIN EN 12600. The standards of the DIN EN 12600 define that the pendulum has to consist of two tires with 3.5 bar pressure and combined 50 kg of weight.

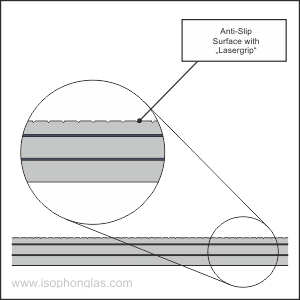

ANTI-SLIP SURFACE DUE TO LASER ENGRAVING

Glass floors need to comply with the applicable standards in terms of static requirements and they also might have to comply with certain regulations and standards in terms of surface treatment in order to prevent slipping.

At isophon glas, we can ensure an anti-slip surface by means of laser engraving of the glass surface. We can deliver anti-slip classifications R 9 and R 10 in accordance with DIN 51130. The classification of the anti-slip surface depends on the site of installation.

With the world’s largest laser engraving system, we at isophon glas are able to process and engrave flat glass with sizes up to 4 x 10 m on the glass surface or inside the glass.

Doing this, we can engrave any desired image or picture on the glass surface or inside the glass. This especially comes to use with our so-called Lasergrip surface treatment for glass floors made by isophon glas.

Lasergrip

Engraving the surface of the glass we can ensure an anti-slip functionality. A treatment like that is especially useful in sanitary areas.

But keep in mind: An increased anti-slip classification leads to increased efforts when cleaning.

SURFACE PROCESSING OF GLASS

We offer all kinds of glass surface processing in addition to the anti-slip surface with laser engraving:

- partial or full-surface sand blasting

- silk screen printing

- etching

- paint coating

- enameling